Manufacturer of Waterjet Machinery, Beyond Cutting Edge

Finecut Micro Abrasive Waterjet Machines

Probably the best micro abrasive waterjet Machines in the world.

Non-Thermal Waterjet Cutting Technology

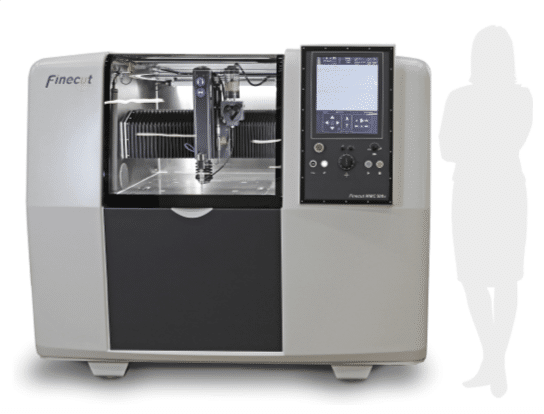

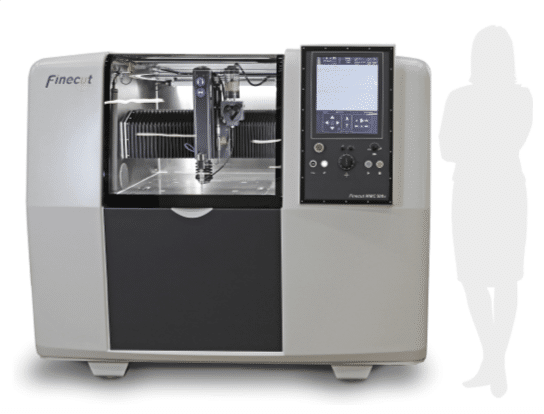

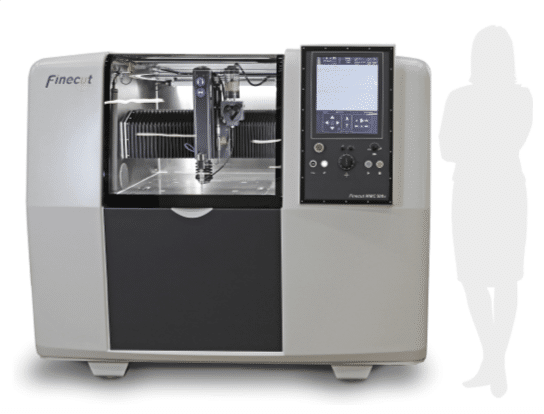

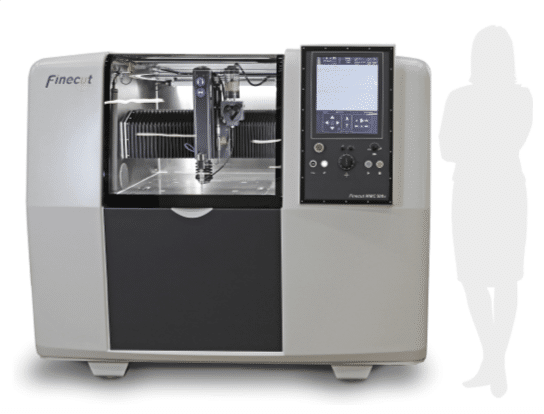

Finepart is the manufacturer of new generation of non-thermal micro abrasive waterjet cutting machines, the world leading Finecut WMC500II, is built by state-of-the-art components to provide capability for your ultimate precision cutting.

The small footprint and encapsulated design make it suitable for any type of workshop environment alongside other CNC machines and sensitive equipment.

Overview Finecut Waterjet Technology

WHAT CAN YOU DO WITH

The Finecut Waterjet Technology

Increase Your Productivity, Cutting Speed, Precision, While Doing Complex Cutting.

3D & Complex Cutting

Higher Cutting Speed

Ultra-High Precision

No Second Finish Need

Eliminate Taper

Non-Thermal Cutting

The Finecut Waterjet machines can increase both your speed and precision, significantly reduce the need for a finishing process, and thereby boost your productivity.

We bring high pressure precision cutting beyond cutting edge, and enable you to cut virtually any material, at ultra-high precision, and cut 3D shapes, at higher cutting speed, and lower material cost.

The Finecut Waterjet MachineS

Benefits & Capabilities

Cut with no thermal influence on the material, thereby a good complement to several other methods e.g., etching and fine stamping for small to intermediate size series.

Ultra-High Precision Cutting

Piercing & Cut in One Set Up

10x Cutting Speed Compared to Wire-EDM

Cut parts up to 30 mm thick in almost any material

Cut Complex 3D Shapes Using 5-Axis Machining

Very Simple to Use

Intuitive Human Machine Interface (HMI), no CNC skills are required.

Perfect Surface Finish

Cut surfaces are burr free and have an excellent surface finish.

Minimal Set Up Cost

Simple and specialized CAD/CAM, including cutting data for most materials.

Higher Profitability

Higher profitability with high cutting speed, precision, intricate cut capabilities.

Finecut Waterjet Machinery Center Overview

Finecut Micro Waterjet Systems

All of our Finecut micro abrasive waterjet solutions are equipped with the latest waterjet technologies, software and features to ensure ultra precise cutting and cutting performance, Beyond Cutting Edge.

FINECUT WMC500II 5X, Type ABX

5 AXIS WATERJET MACHINE

High Speed Precision Cutting For Volume Manufacturing

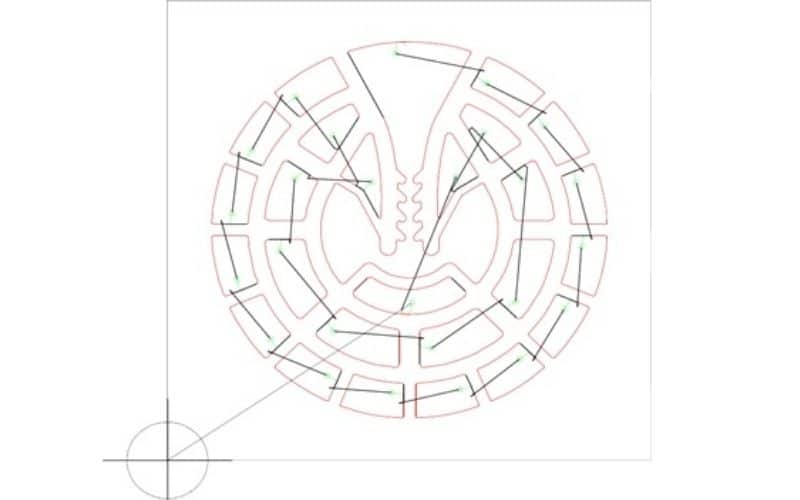

Ideal for volume manufacturing purposes and cutting complex shapes, with cutting width down to 0.3 mm. 5-axis cutting with tool center point control and corner optimization by waterjet motion strategy.

The Finecut 5 axis waterjet technology type ABX, has the cutting-edge capabilities of combining increased cutting speed, ultra-high precision, and three-dimensional cutting, with taper elimination, into ONE single cutting-edge waterjet machining center.

- Cutting envelope: 500 x 500 mm

- Cutting angles up to ± 15º

FINECUT WMC500II 5X, Type B4X

5 AXIS WATERJET MACHINES

High Speed Complex Precision Cutting For Prototyping

Ideal for prototyping or one-off parts and cutting highly complex shapes, with cutting width down to 0.2 mm. 5-axis cutting with tool center point control and corner optimization by waterjet motion strategy.

The Finecut 5 axis waterjet technology type B4X is combing a rotary table with a tilting cutting head and is capable of cutting high inclination angles.

- Cutting envelope: 500 x 500 mm (3 axis mode)

- Cutting envelope 5-axis: ca 370 x 200 mm between centers in A-axis fixture depending on fixturing

- A-axis tilting: ±360º (Can be removed when not used)

- B axis tilting: ±45º

FINECUT WMC500II, 4X

4-AXIS WATERJET MACHINES

Precision with rotating work piece

Ultra high precision cutting with rotating work piece. The A-axis can be fitted with a work table plate on which any work piece can be placed and reoriented to provide access for cutting from different sides of the part.

This motion system setup allows the waterjet nozzle to cut along a contour, following the part’s 3D curvature, moving all four axis in synchronous motion.

- Cutting envelope: 500 mm x 500 mm (3-axis mode)

- Work envelope rotating table: ca 370 x 200 mm between centers in A-axis fixture depending on fixturing

- A-axis tilting: ±360º

FINECUT WMC 500II, 3X

3-AXIS WATERJET CUTTING MACHINE

A versatile precision machine tool

The Finecut™ WMC 500 II 3-axis waterjet machines are a new generation of waterjet technology designed for ultimate precision cutting.

Flexible fixtures for different applications with a cutting width down to 0.2 mm. Highly dynamic and fully encapsulated design. Capable of cutting and following contours in X, Y and Z direction.

- Cutting envelope: 500 mm x 500 mm

Speak With A Waterjet Specialist

Live Demo

Finecut Waterjet Cutting

For a personal demo and the opportunity to get general and technical answers from our engineers

Cutting Ability

Materials You Can Cut

Cut Virtually Any Material With Finecut Micro Abrasive Waterjet Technology

The Finecut micro abrasive waterjet cutting machine is an ultra-accurate non-thermal, high pressure, microcut waterjet system that allows you to cut virtually all materials with superior edge quality. We cut your material no matter if it is very soft materials, ultra-hard materials, or anything in between.

Cutting Edge Waterjet Software

CAD/CAM Waterjet Cutting Software

The IGEMS software is especially developed for waterjet cutting and is included in all Finecut waterjet cutting machines.

The CAD/CAM software easily creates a CNC file which can be transferred to the Finecut operator panel via WiFi or USB.

The different software options will allow you to:

- Draw parts

- Prepare parts for cutting

- Adjust cutting quality

- Adjust cutting parameters

- Calculate cutting time

- Estimate cost of parts

- Get proposal for nesting, and more.

Cutting Edge Waterjet Operator interface

Waterjet Operator System

The Finecut operator panel is a very easy and intuitive Human Machine Interface (HMI) that requires no CNC skills.

- Developed By Finepart

- Easy to understand and operate

- Intuitive interface

- No CNC operator skills required

- Integrated support for options

- Maintenance support, schedule & timers

- Software Upgrades Included

ENHANCE YOUR WATERJET Cutting MACHINEs

Options for Increased Efficiency

Retrofittable Hardware Upgrades. All new and existing options are retrofittable to all waterjet cutters in the Finecut WMC500II series, to increase the efficiency, precision, and capabilities of your Finecut waterjet. Talk to us if you want to upgrade your machine!

High frequency spindle unit for drilling and milling

The spindle is ideal for efficiently piercing through carbon fiber, reinforced plastic materials, aluminum and layered materials, or composite material, that may risk delaminating.

- Excellent for piercing in difficult materials

- End mill up to diameter 4 mm

- Spindle speed 5 000 – 60 000 rpm

- 200 W

Finepart touch probe including software module

The Finepart Touch Probe utilizes the Renishaw LP2DD probe and is useful when you need to position more complex parts for additional machining, and besides finding edges, also require the ability of 3D measurements.

- Accurately set your zero-point

- Locate a hole or boss

- Find an angle on a workpiece

- Locate an edge

- Align workpiece

Work holder – Wave grid

Wave grid holder is a multi-purpose work table solution that helps place material for cutting, quickly. The wave grid uses exchangeable thin deep wave formed slats that support the work piece.

- Quick set-up for cutting parts

- Great part support when cutting

- Exchangeable slats

5-axis Manipulator for higher productivity

The added 2-axis manipulator kit includes high-pressure lines with swivels and provides synchronous A and B axis movement that can tilt the waterjet stream in any direction.

- Cutting width down to 0.2 mm

- 5-axis cutting with tool center point control

- Boosts productivity (+150%) with taper angle control

- Corner optimization by jet motion strategy

5-Axis Manipulator for advanced single part production

The 5-axis type B4X facilitates is a combination of a B axis tilting the waterjet cutting head up to ± 45º degrees and a table-mounted A-axis that manipulates the work piece.

- Cutting width down to 0.2 mm

- Perfect for prototyping

- 5-axis cutting with TCP control

- 3-dimensional (3D) cutting with high inclination angles and complex shapes

High pressure water pump

The water pressure intensifier pump is a high pressure water pump technology, with durability that provides continuous top performance.

- Efficient High Pressure Pump 4.000 bar / 22kW

- Can Be placed remotely from the Finecut waterjet

- Comfortable operation via touch panel on Finecut waterjet system

- Optional remote diagnostics / safety due to remote access

Service & Support

Finepart Academy

Access to courses, operator certification, service technician training.

Machine Training

On-site training during machine start up, follow-up training for operators.

Service & Support

Service and maintenance agreement for fast and reliable on-site, and remote service.

Software Upgrades

Software is upgraded during on-site visits for support or maintenance.

Speak With A Waterjet Specialist

Customer stories

FAQ – Finepart Waterjets

What abrasives can be used?

Most dense materials of higher strength will require that you add abrasive material in the waterjet stream in order to achieve an efficient cutting process. You can use abrasive of different materials and sizes. Select the type of abrasive particles with respect to the hardness of the material you intend to cut, the size of the focus tube etc.

How fast can a waterjet cut?

The cutting speed depends on the properties and thickness of the material. Thicker and harder materials require a slower cut. If you want a smooth material surface the cutting speed needs to be reduced.

The Finecut water jet cutting machine can move the cutting head with a speed of 20 m/min but it is very few materials that actually can be cut with this speed. As with any abrasive waterjet machine, the cutting speed will affect the quality of the cut. As an example, the FAW300 cutting system can make a separating cut in 3 mm thick stainless steel at 300 mm/min. but more often a cutting speed of 60 mm/min., or even 30 mm/min., are selected depending on the application and precision requirements.

How thick can a water jet cutter cut?

Finecut waterjet cutters can cut materials up to 30 mm thickness but there are always exceptions depending on material properties and quality requirements. If you need to cut thicker parts you can fit an abrasive waterjet cutting system in the machine, which is available as an option to all Finecut waterjet cutters. The slower you cut, the thicker and harder the material can be. It means that you can cut thick material but the cutting speed will decrease.

Can you remove material without cutting through?

Yes, the Finecut water jet cutting machine can be used for milling purposes. In fact, milling capability has been one of its design criteria. The encapsulated design and powerful direct drive motion system makes it suitable for milling. The control system has look-ahead as well as machining condition selection function, the latter allowing to have different servo parameter settings, optimizing either velocity or path accuracy.

How much space is required for the Finecut system?

The Finecut system is easy to place in a normal workshop. Since the machine is encapsulated it can be situated next to other precision CNC machines. If a small footprint is important, the high-pressure pump can be placed at a remote location. The Finecut machine itself has a footprint of 2 by 1.5 meter (6.6 by 4.9 foot).

Do I need experience in waterjet cutting in order to operate the Finecut waterjets?

No, you do not need experience in waterjet cutting nor experience in CNC programming or others. The Finecut WMC500II has a unique intuitive HMI (human machine interface) which is very easy to learn, use and operate. The interface is modern with apps and symbols you know from your daily life.