CASE

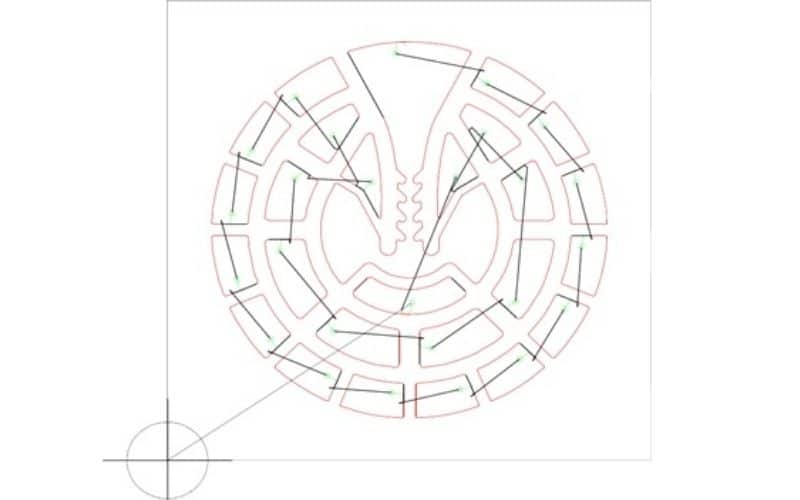

Surgical clip in Nitinol

The Surgical clips are used in Laparoscopy. Examples of applications are to close veins or blood vessels inside the body. These can be manufactured in different materials. In the present case, Nitinol (shape-memory alloy) is used which, besides having the property that it can be “programmed” to regain a desired shape, it has super-elastic properties that enables opening and closing it.

There are high demands on surface integrity. The product must be free of burrs and oxides. Previously, the customer has processed these products with a water jet guided laser. This has limitations with a machining speed of about 30 mm/min and heavy slag formation. Subsequent electropolishing was required. Alternative machining methods was performed with Finecut micro abrasive waterjet machine from Finepart Sweden AB with the below conclusions.

Data

Material

Material thickness

Length of cut

Annual volume

Nitinol

1.1 mm

138 mm

5 000 pcs

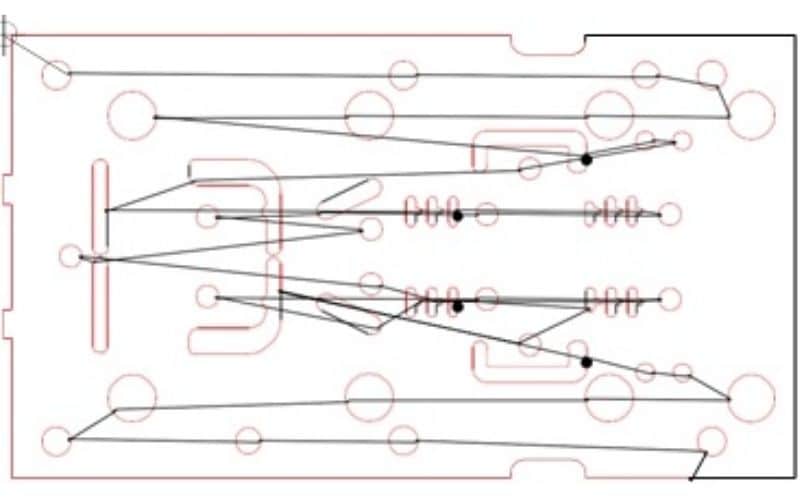

Cutting with Finecut machine

Cutting system

Number of set ups

Average cutting speed

Operational cutting time

Finecut operational cost

FAW200

1

72 mm/min

110 sec

0.49 €/pc

Conclusion from the Finecut test

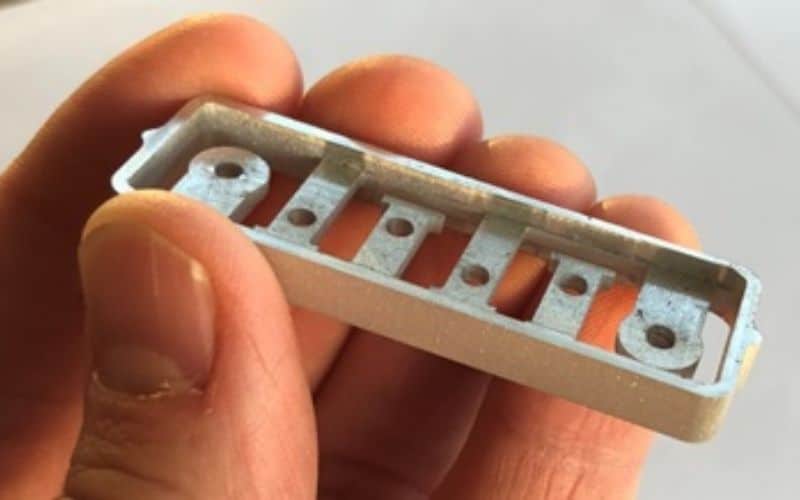

- Sections of the part is down to 100 µm wide.

- The components show no generated burrs, oxides or heavy slag formation after cutting

- The typical tolerances of component are within ±10 µm

- No changes in the material structure after the cutting

- Surfaces were polished with Finespin magnetic polishing